Why Use a Binding Machine?

- participación

- Tiempo de Publicación

- 2017/7/14

It has never been simpler to produce professionally bound documents. Business communications are becoming increasingly sophisticated and many more offices nowadays have access to desktop publishing systems, colour laser printers and colour copier / printers. As a result, an ever-increasing number of companies and other institutions and bodies are producing their own sales material and other documentation to a very high standard. However, any printed material will look even more professional and consequently have greater impact if it is presented as a properly bound document.

There are a number of reasons why you might choose to bind documents. You might be creating a presentation, binding a quotation for a customer, binding a hand-out for students, or simply organising your documents. Human resources departments bind policy documents, training manuals and development plans. Accounts departments might need to bind suppliers’ details, year-end accounts or monthly reports. Purchasing departments bind supplier proposals, contracts and agreements. Design departments bind product designs and reference manuals. Production departments might bind Health & Safety manuals and procedures. Sales and Marketing departments bind sales proposals, sales reports and marketing plans. The benefits of using binding machines include the following :

You present a better image. A professional, high quality image reflects well on you and your organisation.

You enhance usability. Bound documents are easier to handle, discuss, photocopy, store and reference.

You protect and preserve documents. Protect and preserve the papers which otherwise can become dog-eared with age and frequent use.

You add style and colour. A wide choice of covers, combs, wires and wrap covers can add colour and style to any document.

Which type of binding machine do I need?

Just as there are a number of reasons why you might choose to bind documents, so are there similarly a number of different types of binding and this page is to help you to determine which particular type of binding is the most suitable for your particular requirements. One of the questions you need to ask yourself is how many books a day will you need to produce? If only a few documents a day need to be bound then a low volume binder would probably suit. If the figure is higher, i.e. scores of documents per day then something with a reasonable punching capacity would be better. If the number of books or documents that need to be bound in a day runs into the hundreds, then it might well be better to choose a machine with an electric punching facility.

What are the various different types of binding method?

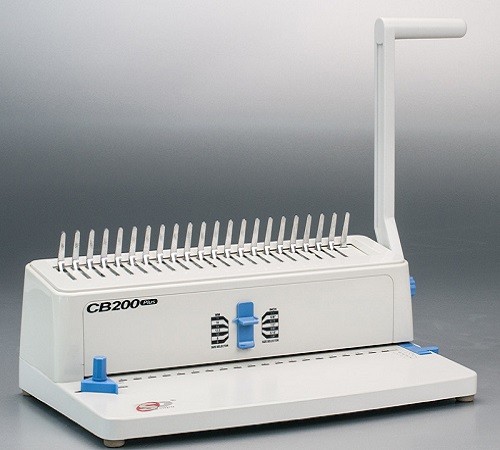

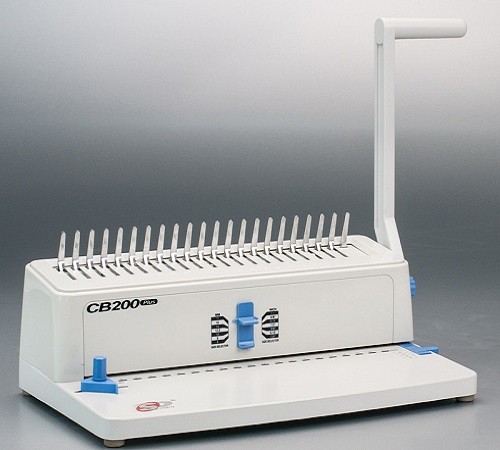

Comb binding is by far the most popular and economical binding system available. The plastic combs are strong and reusable as well. Comb binding is quick and simple and suits a wide range of user needs. Schools, business and colleges seem to prefer comb binders. Machines come with either a manual or electric punch. The paper is punched firstly, then the comb is placed on the machine where, by pulling a handle, the comb opens for the operator. The punched paper is placed over the holes and by releasing the handle you allow the comb to close again. Comb binding offers total flexibility as the smallest document of only two pages right up to a report of 500 pages can be bound using this method, with ease. Documents can be created from a wide variety of colours, textures and sizes.

Comb binding is also very practical. Comb bound documents open out completely flat and are consequently ideal for presentations and easy reading. This also makes them easy to photocopy if required. The bound pages are completely secure yet easy to update when required as bound pages can be added or removed when required. Comb binders range from a compact budget machine up to the convenience of electric punch models. All of these machines will create professional documents in minutes.

Wire binding produces professional looking documents that not only look good but are also again very easy to use. Wire binding enables you to create in your own office the same durable, elegant look that is used by professional printers. Wire bound documents are completely secure yet the pages open easily, can again be laid flat or even turned through 360° for easy reference and photocopying. Wire bound documents look smart and business-like, have a contemporary look and are just the right image for any organization. There are basically two popular types of wire binding. These are 2:1 pitch and 3:1 pitch, which basically means that the machine will punch two holes and three holes per inch respectively

2:1 pitch gives 21 holes in the paper and will accommodate from 20 up to 230 sheets of paper.

3:1 pitch will give 32 holes and is suitable for paper thicknesses of 10 pages up to 120 pages.2:1 pitch

Thermal binding is ideal for all kinds of documents, form instruction manuals to staff or internal telephone directories. Thermal binding provides permanent permanent protection for all your important reference material and the finished result is extremely smart. Thermal bound documents are neat and flat, making them easy to store, carry around and post. Thermal binding is the ideal binding method when time is limited. Simply place the loose pages of your document into a thermal cover, wait a few seconds for the binding machine to reach temperature, and then place your document inside. Within seconds you will have a smart, permanently bound document. One of the benefits of thermal binding is that you can create a professional finished look without punching holes into your document.

Perfect binding uses the thermal binding process but is for much higher output. Typically, a perfect binder would be perfect for commercial printers, copyshops, reprographic departments, print-on-demand units and implants. The innovative binding process means no fuss, no fumes, no noise, no mess and yet they are easy to use. These are sturdy units that give a unique and permanent finish to perfect bound books and documents. Up to 300 books each of 200 pages can be produced on a perfect binding machine.

Tape binding equipment uses the thermal binding process also. A high quality appearance but the process eliminates the time spent and the costs incurred by punching each set of documents.

Click Binding produces elegant documents and also produces greater flexibility. You can quickly open, add or remove and re-close any document as often as you like. The combs open and close with an action not unlike a zip fastener and are extremely durable.

Coil Binding is innovative and stylish. This is one of the most impressive binding styles used today. The bright coil hNEWs its shape well and bounces back if compressed, making it ideal for posting. Coil bound documents demand immediate attention and open 360 degrees. Coil binding uses a continuous PVC filament formed into the shape of a coil spring. It is very similar to the binding found in spiral notebooks. You will need to cut and crimp the end of the spirals when binding. Some machines are motorized and have a coil inserter which turns the coils through the holes. However, most coil binding machines need the operator to insert the coils manually. The machines take 4:1 pitch and 5:1 pitch coils.

4:1 coils will take up to approximately 230 sheets of paper.

5:1 coils will take up to approximately 150 sheets of paper.

Strip binding using SureBind and Velobind machines, produces professional flat bound documents. Velobind enables users to produce prestigious looking documents right at their desk and for a budget price. Surebind is a totally secure, tamper-proof binding method, ideal for legal or confidential documents. Pages are locked into place by welding two halves of the binding strip together. Documents up to 3 inches thick can be bound this way.